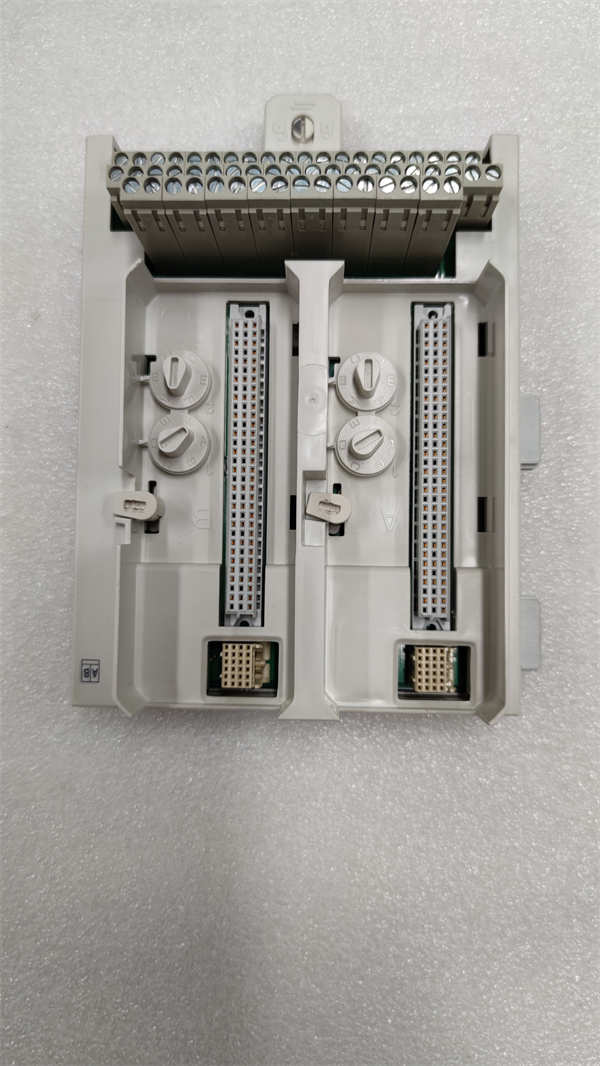

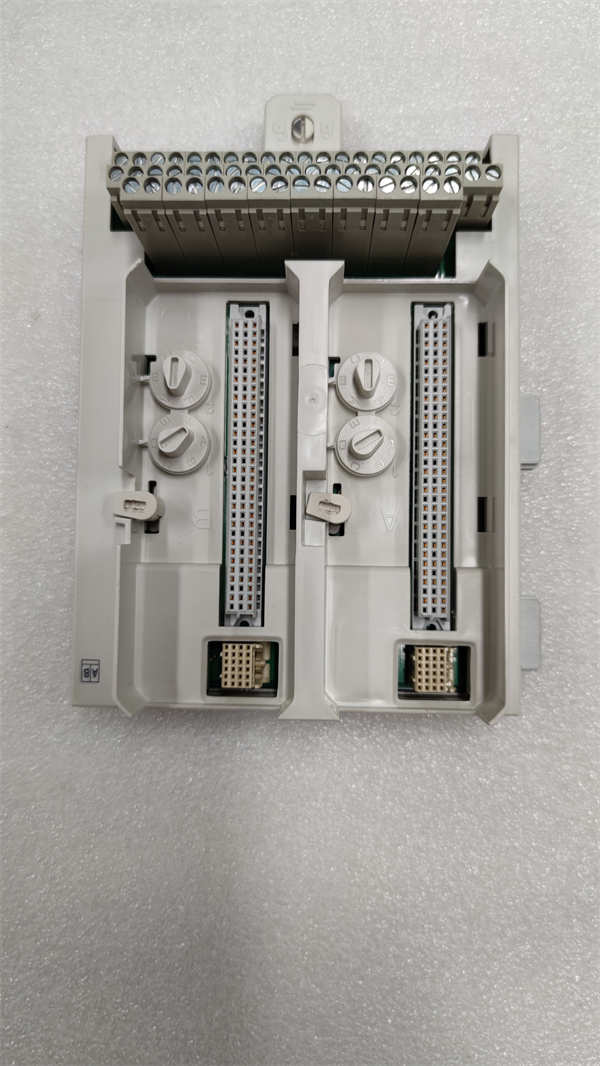

ABB TU842

Detailed explanation of ABB TU842 module terminal unit products

Product Overview

TU842 is a module terminal unit (MTU) in ABB S800 I/O system, mainly used to carry S800 I/O modules. It provides a safe and reliable installation environment for I/O modules, ensuring their normal operation.

ABB TU842

Product features and functions

Modular design: allows users to flexibly add or remove I/O modules to meet different application requirements.

High channel density: Compared to other MTUs, TU842 typically has a higher channel density and can carry more I/O modules in limited space.

Safe and reliable: Provide a secure operating environment to protect modules from damage.

Strong scalability: Supports multiple I/O modules to meet different types of input and output requirements.

Key control design: prevent module installation errors and improve system reliability.

Product parameters and specifications

The specific specifications of TU842 may vary depending on the model and configuration. We recommend that you refer to ABB's official product manual for detailed parameter information.

Generally speaking, the product manual will include the following information:

Physical dimensions: including height, width, depth, etc.

Weight: The weight of the product.

Installation method: How to install it on the control cabinet or chassis.

Environmental requirements: working temperature, humidity, etc.

Electrical parameters: voltage, current, etc.

Number of Load Modules: How many I/O modules can be carried.

Communication interface: The method of communication with other devices.

Number of channels: How many I/O channels can each TU842 provide.

Series Introduction

TU842 belongs to ABB S800 I/O system. This system is a comprehensive distributed modular process I/O system that can communicate with the parent controller through industry standard fieldbus. It has high reliability, high availability, and high scalability, and is widely used in the field of process control.

ABB TU842

ABB TU842

Usage and Application Fields

TU842 is mainly used for:

Process control: Used in various industrial processes to collect and control on-site signals.

Automation system: As the I/O interface of the automation system, it enables communication with on-site devices.

Data collection: Collect on-site data for monitoring and analysis.

Typical application areas include:

petrochemical industry

energy

water treatment

pharmacy

Food and Beverage