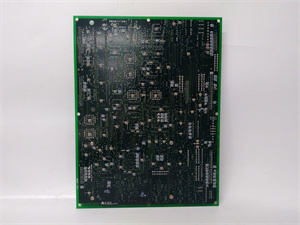

GE DS200LDCCH1ALA is a drive control and fire communication board produced by General Electric (GE), mainly used for Mark V series turbine control systems. As a part of the control system, it is responsible for driving control, data communication, and other functions

Drive control: Provides control functions for drive equipment, such as motor start, stop, speed adjustment, etc

Fire communication: Communicate with other devices through LAN interfaces to achieve data exchange and system integration

High connectivity: Adopting industrial grade design, suitable for Ethernet industrial environments

Recommended design: As part of the Mark V system, it can be flexibly combined with other modules

Product Parameters (Partial)

Communication interface: LAN

Processor: Multiple (DCP, LCP, MCP, CMP)

Input/Output: Digital Input/Output, Analog Input/Output

Working voltage: According to system requirements

Working temperature: According to system requirements

Compliant with standards: Compliant with relevant industry standards

Protection level: Select according to installation environment and requirements

EMC performance: meets EMC requirements and ensures electromagnetic compatibility

DS200LDCCH1ALA belongs to the GE Mark V series, which is a steam turbine control system launched by GE and widely evaluated in the power industry

Performance: Mass processing, improving system response speed

Flexibility: Multiple functions can be achieved through software configuration

After long-term application verification, it has high reliability

Drive control: Control the turbine drive system to adjust parameters such as power

Data communication: exchange data with other devices to achieve system integration

Signal processing: Processing digital and analog signals

Main applications:

Turbine control system: As the core component of the Mark V system, responsible for driving control and communication

Power industry: power plants, substations, etc

Electricity production: Steam turbine control center

Energy Industry: Developing National Automation