PRODUCT

PICTURE

BRAND

DESCRIBE

STOCK

DOWNLOAD

Model Number P0972QR Product Type Gauge Pressure Transmitter (measures pressure relative to atmospheric pressure) Sensor Technology Silicon Resonant Sensor Output Signal 4-20 mA analog output with superimposed HART® Protocol (Version 5/6/7) for digital communication. Accuracy Exceptional: ±0.075% of URL (Upper Range Limit) for spans ≥ 3 bar (43.5 psi). This is a key feature of this model. Long-Term Stability ±0.1% of URL per 12 months. Pressure Ranges (URL) Available in many standard ranges, e.g., 0-1 bar (0-15 psi) up to 0-400 bar (0-6000 psi). The exact range is specified when ordering. Process Connection Standard: 1/2-14 NPT internal thread. Other connections like G1/2" may be available. Wetted Parts Material 316L Stainless Steel (standard for diaphragm and process connections). Power Supply 2-wire, 12-45 VDC (loop-powered). Operating Temperature Electronics: -40°C to +85°C (-40°F to 185°F). Process Media: -40°C to +125°C (-40°F to 257°F). Protection Rating NEMA 4X / IP67 (weatherproof, dust-tight, and submersible).

Model Number AD204WEB Function Type 4-Channel Analog Input Signal Conditioner / Isolator Input Signal 4-20 mA (accepts current signals from field transmitters) Output Signal 4-20 mA (isolated current signal output to the control system) Number of Channels 4 channels, with full isolation between channels and from the power supply. Power Supply Typically requires an external power source, such as 24 VDC. Accuracy High typical accuracy, e.g., ±0.05% of span. Isolation Channel-to-channel isolation and channel-to-power isolation (typically 1500 VAC), preventing ground loops and signal noise. Load Capacity The maximum load resistance the output can drive (e.g., 0-600 Ω). Response Time Very fast, typically less than 100 ms. Operating Temperature -40°C to +85°C, suitable for harsh industrial environments. Mounting Standard 35mm DIN rail mounting. Certifications Typically carries international certifications like CE, ATEX (for hazardous areas), IECEx, FM.

Model Number E69F-B18-M Product Type Vortex Flowmeter Measurement Principle Vortex Shedding (von Kármán Effect) Process Connection Flanged, per ANSI B16.5 Class 150 or Class 300 (dependent on order code). Common sizes range from 1" to 8". Meter Body Material Carbon Steel Measured Media Liquids, Gases, Steam Accuracy ±1.0% of reading for liquids ±1.5% of reading for gases and steam (at specified flow rates) Rangeability / Turndown Typically 10:1 or better, offering a wide measuring range. Output Signals • 4-20 mA analog output (proportional to flow rate) • Pulse/Frequency output (for totalization or high-resolution flow) • HART® Protocol for digital communication, configuration, and diagnostics. Power Supply Standard: 12 to 45 VDC (2-wire loop-powered) Temperature Limits Process Temperature: Up to 400°C (752°F) or higher, dependent on sensor option. Ambient Temperature: Standard electronics: -40°C to 85°C (-40°F to 185°F). Pressure Rating Dependent on flange class. Example: ANSI Class 300 flange is rated for approximately 50 bar (725 psi) at 38°C (100°F). Enclosure Rating Typically NEMA 4X / IP67 (dust-tight, watertight, and corrosion-resistant).

Model Number P0916KH-0B Product Line Foxboro I/A Series Module Type Redundant, Hot-Swappable AC/DC Power Supply Module Key Function Provides high-wattage, fault-tolerant power for high-density I/A Series nodes. Input Specifications Input Voltage Wide-range AC input, typically 90-264 VAC, automatically sensed. Input Frequency 47 - 63 Hz (compatible with 50Hz/60Hz power grids). Power Factor Correction (PFC) Active PFC (Power Factor Correction) is standard for high-power modules to meet efficiency regulations. Output Specifications Output Voltages Provides the standard, isolated DC voltages for the I/A Series backplane: • +5.1 VDC (for digital logic circuits) • +24.8 VDC (for field I/O power) • ±15.2 VDC (for analog circuit power) Total Output Power High Capacity, estimated 1600 Watts (based on the "16" suffix). The exact wattage per voltage rail must be verified. Redundancy Designed for N+1 Redundancy. Modules operate in a current-sharing, load-sharing mode. Protections Comprehensive suite including: Over-Current (OCP), Over-Voltage (OVP), Over-Temperature (OTP), and Short-Circuit protection. Physical & Operational Mounting Slides into a dedicated bay in a redundant power chassis (e.g., a PSS31 rack). Hot-Swappable Yes. Designed for insertion and removal under full load without disrupting system operation. Cooling Internal, forced-air cooling with fans. Fan status is typically monitored. Status Indicators (LEDs) Comprehensive LED indicators for: • AC Power Present • DC Output OK • Unit Failure • Load Sharing Active • Replace Indicator Communication May include a communication link for reporting status, alarms, and metrics (e.g., output current, temperature) to the system for monitoring. Environmental Operating Temperature 0°C to +60°C (with derating at the upper end of the temperature range). Efficiency High efficiency, typically > 85% or 90%, to minimize heat generation and energy loss.

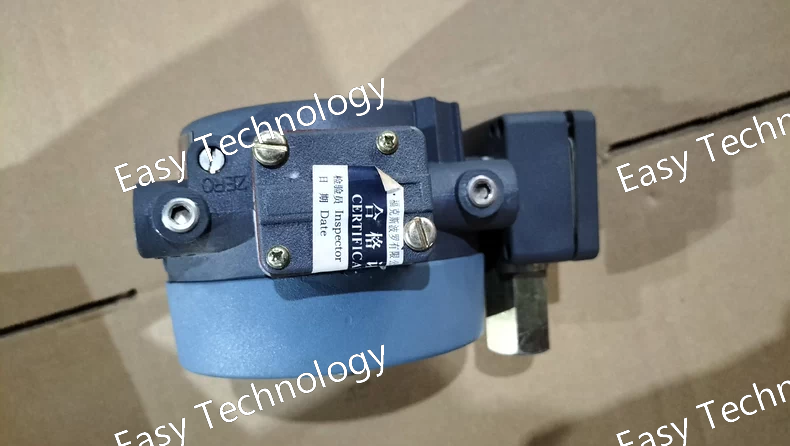

Model Number SRD960-BHQDSN7EDZFA Type Smart Electronic Valve Positioner Supply Air Pressure 1.4 - 7 bar (20 - 100 psi) Action Single-acting (for spring-return actuators) Ambient Temperature -30°C to +80°C (-22°F to +176°F) Input Signal 2-wire, 4-20 mA DC (Loop powered) Load Resistance Typically up to 850 Ohms at 20 mA (dependent on air supply) Communication HART® protocol (standard for digital communication) Performance Accuracy Typically ≤ ±0.5% of span Hysteresis Typically < 0.1% Linearity Typically < 0.1% Mechanical & Physical Housing Protection IP66/67 (NEMA 4X equivalent) - Dust-tight and protected against powerful water jets and temporary immersion. Mounting Direct mounting per VDI/VDE 3845. Adapter kits available for other standards. Pneumatic Connections FA = 2 x 1/4" NPT internal thread Electrical Connection Z = Cable gland M20 x 1.5

System Name Foxboro MICRO-I/A Type Compact Distributed Control System (DCS) Key Characteristics Integrated controller & HMI, ruggedized design, true DCS functionality for small to medium applications. Hardware Components Controller Modules (CM) e.g., CM400 Series (like the CM400TH). These were the core processors, often featuring integrated displays and keypads. I/O Expansion Supported connection to remote I/O racks using Foxboro's FBM (Field Bus Module) series, the same I/O modules used in the larger I/A Series. This ensured compatibility and scalability. Power Supplies Dedicated power supply modules for the controller and I/O racks. Software & Configuration Engineering Software Configured using Foxboro's I/A Series software tools (like the Foxboro Control Core) on a Windows-based PC, ensuring commonality with the larger I/A Series. Control Languages Supported standard DCS and PLC languages: Continuous Function Chart (CFC), Ladder Logic (LD), Sequential Function Chart (SFC), Structured Text (ST). Communication & Networking Peer-to-Peer Communication Micro-I/A stations could communicate with each other over a network. Integration with I/A Series Could be seamlessly integrated as a node into a larger Foxboro I/A Series DCS network via Nodebus or other supported protocols. Open Protocols Supported industry-standard protocols like Modbus TCP/IP and Modbus RTU for connecting to third-party devices (PLCs, drives, etc.) and systems. Physical & Environmental Enclosure Modules were designed for panel mounting with a high degree of integration. Environmental Rating Typically NEMA 4X / IP66 for the controller, allowing installation in harsh industrial environments (dust, water sprays, corrosion). Operating Temperature 0°C to +60°C (32°F to 140°F) standard.

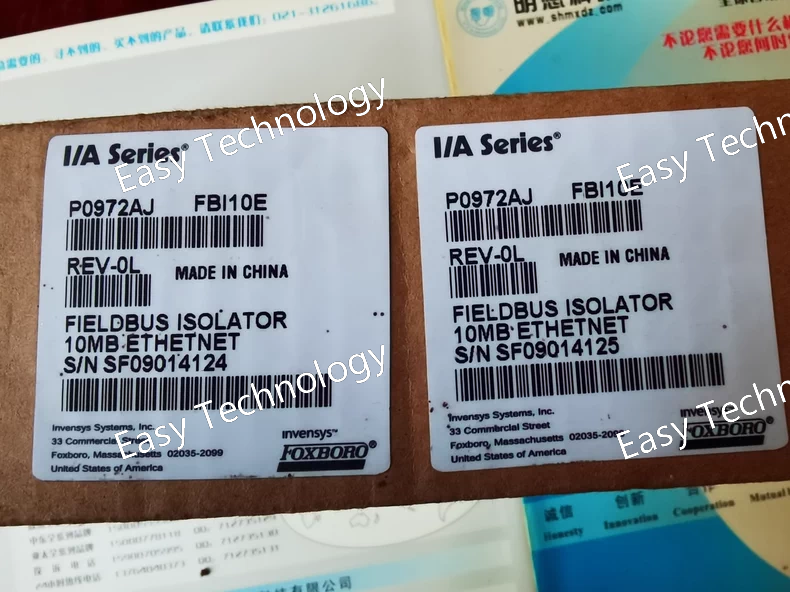

Model Number P0972AJ Product Line Foxboro I/A Series Component Type Fan Assembly / Cooling Module Key Function Provides forced-air cooling for modules within a PSS rack to prevent overheating. Electrical Specifications Input Voltage Powered by the rack's internal DC power bus, typically +24 VDC or +48 VDC. Power Consumption Low power draw, specific to the fan motor (e.g., 10-30W). Physical & Performance Airflow Designed to deliver a specific Cubic Feet per Minute (CFM) to meet the thermal dissipation requirements of the rack. Fan Speed May be fixed speed or have temperature-controlled variable speed. Mounting Slides into a dedicated slot within the PSS chassis, aligned with the cooling vents of the modules. Hot-Swappable Yes. Designed to be inserted and removed without requiring a system shutdown. Redundancy Often used in a redundant (N+1) configuration. If one fan fails, the remaining fans provide sufficient cooling. Status Monitoring Includes a feedback signal (e.g., a tachometer output or alarm contact) to monitor fan operation and detect failures. Connector Uses a specific electrical connector to interface with the rack's backplane for power and status signaling. Environmental Acoustic Noise Specified to operate below a certain dB(A) level. Operating Temperature Rated for the same ambient temperature as the rack, typically 0°C to +60°C.

Model Number 871A-1F Product Line Foxboro 800 Series Instrument Type Differential Pressure (DP) Transmitter Output Signal 2-Wire, 4-20 mA DC, HART® protocol enabled (for digital communication). Power Supply Typically 12-45 VDC (loop powered). Performance Accuracy High accuracy, typically ±0.25% of span (including linearity, hysteresis, and repeatability). Turndown Ratio High turndown (e.g., 10:1), allowing for wide rangeability. Response Time User-adjustable damping. Pressure Ratings Line Pressure Specific maximum static pressure rating (e.g., 3600 psi / 248 bar) depending on the "1F" flange rating. Overpressure Protection Capable of withstanding high overpressures without damage. Materials of Construction Wetted Parts The "1F" code specifies materials. Common options include 316 Stainless Steel for isolating diaphragms and Hastelloy C-276 for corrosive services. Electrical Connection Likely ½” NPT conduit connection. Process Connections Typically ¼” NPT or ½” NPT female ports on the high and low pressure sides. Environmental Operating Temperature -40°F to +185°F (-40°C to +85°C) for the electronics. Wider range for the sensor. Ambient Temperature Effect Minimal span and zero shift per degree temperature change. Humidity 0-100% RH (non-condensing). Enclosure Rating NEMA 4X (weatherproof and corrosion-resistant).

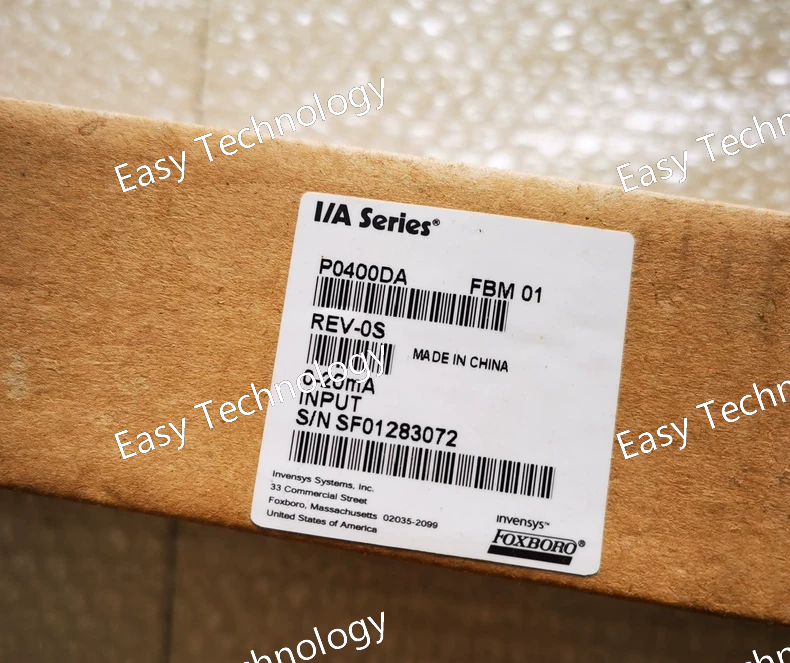

Model Number P0400DA Product Line Foxboro I/A Series Module Type Control Processor (CP) Key Function Executes control logic, manages I/O modules, and handles system communications. Performance Processing Capability Suitable for moderate-complexity continuous and batch control applications. Capable of handling a defined number of PID loops and logic points. Memory Specific capacity for user logic and configuration. Control Scan Rate Configurable scan periods (e.g., 100 ms, 200 ms, 1 s). Input/Output (I/O) Management Supported FBMs Manages a complement of various Field Bus Modules (digital, analog, etc.). I/O Capacity Supports a maximum number of I/O points (e.g., up to 1024 points), dependent on FBM types and configuration. Communication Interfaces Nodebus Communicates with other control processors and application workstations (AWs) over the high-speed Nodebus for peer-to-peer communication. Fieldbus Communicates with Field Bus Modules (FBMs) over the Fieldbus network. Redundancy Redundancy Support Typically supports 1:1 Redundancy. Can be paired with an identical CP for bumpless failover, ensuring high availability. Physical & Environmental Mounting Installs into a slot in a Foxboro PSS (Power Supply System) rack. Operating Temperature 0°C to +60°C (standard industrial range). Status Indicators (LEDs) Comprehensive LEDs for Power, Run, Fault, Primary/Standby status, and communication activity.

Model Number P0916NG0D Product Line Foxboro I/A Series Module Type Redundant, Hot-Swappable AC/DC Power Supply Module (New Generation) Key Function Provides high-wattage, fault-tolerant power for high-density and high-availability I/A Series nodes. Input Specifications Input Voltage Wide-range AC input, e.g., 90-264 VAC, automatically sensed. Input Frequency 47 - 63 Hz (Compatible with 50Hz/60Hz). Power Factor Correction (PFC) Active PFC (standard for high-power, modern supplies to meet efficiency regulations). Output Specifications Output Voltages Provides the standard, isolated DC voltages for the I/A Series backplane: • +5.1 VDC (Primary logic power) • +24.8 VDC (Field I/O power) • ±15.2 VDC (Analog circuit power) Total Output Power High Capacity, estimated 1600 Watts (based on the "16" suffix). Redundancy Designed for N+1 Redundancy with current-sharing (load-sharing) operation. Protections Comprehensive: Over-Current (OCP), Over-Voltage (OVP), Over-Temperature (OTP), and Short-Circuit protection. Physical & Operational Mounting Slides into a dedicated bay in a redundant power chassis (e.g., a PSS31 rack). Hot-Swappable Yes. Designed for insertion and removal under full load. Cooling Internal, forced-air cooling with fans. Fan speed may be temperature-controlled. Status Indicators (LEDs) Comprehensive LED indicators for: • Input AC OK • Output DC OK • Unit Failure • Load Sharing Status • Replace Indicator Communication & Monitoring Likely includes advanced communication (e.g., via a serial link or dedicated pin) for detailed status reporting, alarm logging, and performance metrics (e.g., output current, temperature) to the control system. Environmental Operating Temperature 0°C to +60°C (with derating at high temperatures). Efficiency High efficiency, typically > 90% for the "NG" generation, reducing energy loss and heat generation.

Model Number P0972QM-0C Product Line Foxboro I/A Series Component Type Redundant, Hot-Swappable Fan Assembly / Cooling Module Key Function Provides forced-air cooling for high-density power supply modules in a PSS rack. Electrical Specifications Input Voltage Powered by the power supply rack's internal DC bus, typically +24 VDC or +48 VDC. Fan Speed May operate at a fixed speed or have speed control based on temperature. Physical & Performance Airflow Designed to deliver a specific Cubic Feet per Minute (CFM) or cubic meters per hour (m³/h) to meet the cooling requirements of the associated power supplies. Mounting Slides into a dedicated slot within the power supply chassis, aligned with the cooling vents of the PSUs. Hot-Swappable Yes. Designed to be replaced without powering down the entire power system, ensuring continuous cooling. Redundancy Often used in a redundant (N+1) configuration. If one fan fails, the remaining fans can provide sufficient cooling. Status Monitoring Includes a sensor (e.g., a tachometer signal or Hall-effect sensor) to monitor fan speed and detect failures. Connector Uses a specific electrical connector to interface with the rack's backplane for power and status signaling. Environmental Acoustic Noise Specified to operate below a certain dB(A) level for acceptable noise in the control room environment.

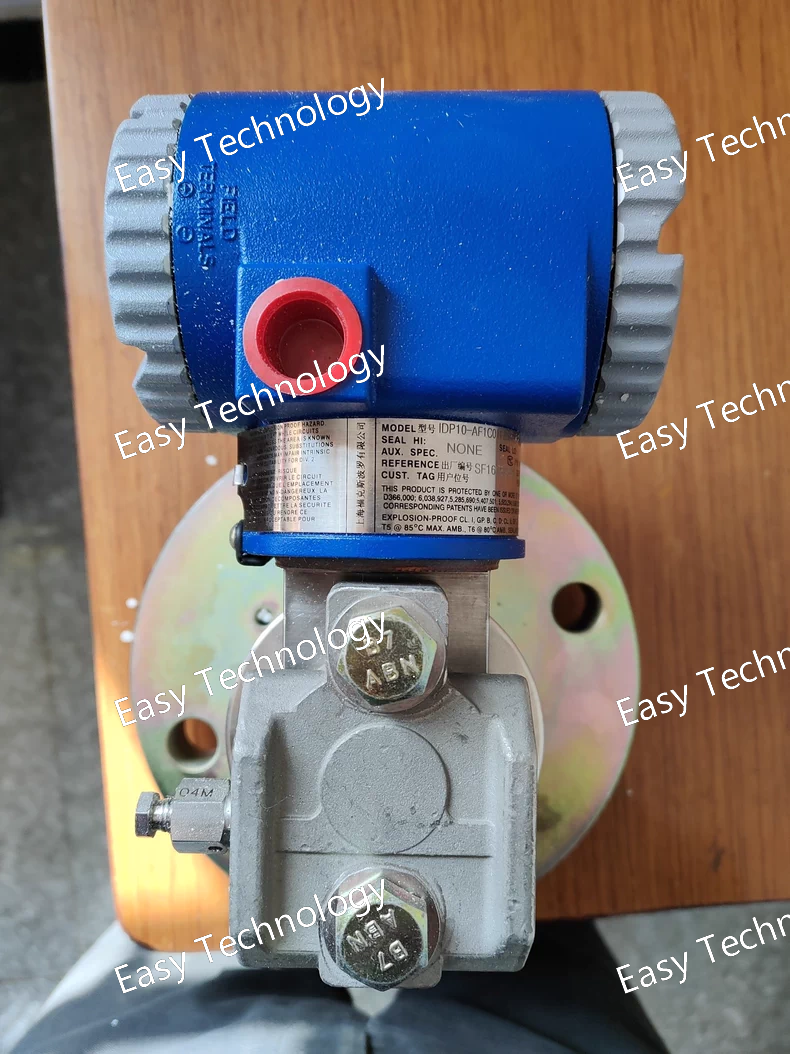

Model Number IDP10-AF1C01F Product Line Foxboro I/A Series Module Type Single-Channel, Isolated Frequency / Pulse Input Conditioner Key Function Conditions and measures frequency or pulse train signals from field devices. Input Specifications Supported Input Signal Pulse or Frequency Input (e.g., from a turbine flow meter, vortex flow meter, or tachometer). Input Type Typically accepts Namur proximity sensor compatible signals or OC (Open Collector) transistor pulse signals. Frequency Range A specific range defined by the "F1C" code (e.g., 0 Hz to 10,000 Hz). The exact range must be verified from the data sheet. Input Voltage Levels Designed for low-voltage pulse signals (e.g., 0-30 VDC). Minimum Pulse Width The module can recognize a minimum pulse duration (e.g., 50 μs). Isolation Channel-to-System (Field-to-Logic): 1500 VAC RMS continuous. Provides protection against ground loops and transients. Output Specifications Output to System A digital value (e.g., totalized pulse count or computed frequency) communicated digitally over the FBI bus to the host controller. Scalability The pulse count or frequency can be scaled within the DCS software to represent engineering units (e.g., liters/min, gallons, RPM). Power Supply Operating Voltage Powered by the +5V and ±15V supplies from the PSS baseplate. Sensor Power May provide a loop power voltage (e.g., 8.2 VDC) for 2-wire Namur sensors. Physical & Environmental Operating Temperature -40°C to +70°C (-40°F to +158°F) Mounting Installs into a dedicated Foxboro PSS series baseplate. Status Indicators (LEDs) Typically includes LEDs for Power (PWR) and Input Status (e.g., pulses detected).